|

Documents

|

Home » Handheld-automatic-screwdrivers

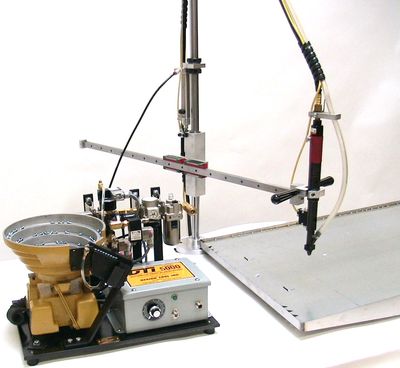

Screwdriver Torque Arms Torque Arms are used to reduce operator fatigue, arrest the torque reaction of the driver, and maintain vertical driver alignment to insure that the fastener is driven straight. Torque Arms also are equipped with tool balancers to support the weight of the screwdriver assembly. Design Tool Inc. offers three different types of torque arm designs to meet varying customer requirements. The three basic types offered are linear, articulating, and air assist torque arms. Choosing the correct arm is dependent upon the application requirements. The DTI 400 linear torque arm features positive torque arrest to prevent operator fatigue. It is available in 24 and 36 inch reach configurations, and offers both single and dual tool balancers to handle a variety of driver sizes and weights. The linear arm has twin horizontal rod and bearing assemblies to maintain vertical driver alignment and pivots around a single vertical rod and bearing assembly that has a balancer height of 36 inches. The vertical bearing assembly can pivot 360 degrees, but most assembly stations use it 180 degrees or less. The DTI 300 articulating torque arm pivots around a vertical swivel mount and has an articulating joint between the vertical swivel mount and the driver mount. This design allows the driver to reach almost any screw position within a 20 inch circle. The articulating arm uses an air cylinder to support the tool reducing the force required to raise the tool. An air pressure regulator is used to control the amount of lift provided by the cylinder. The driver can be mounted in a swivel configuration as well, allowing the operator to pivot the driver to avoid obstacles in the assembly environment. The DTI 600 air assist torque arm combines the linear design capabilities of the DTI 400 with an air cylinder to provide down force to drive the screw thus reducing or eliminating the force that the operator must provide to drive the screw. The air assist torque arm can be actuated by different methods depending upon the customer requirements and safety considerations. These torque arms offer a real advantage to customers using self-tapping screws into metal and plastic applications by reducing operator fatigue and helping to eliminate repetitive motion injuries. Please call us to discuss your options. Additional Images

|